We're developing a technology to measure volume with sound. It lets us control crunchiness and that mouth-melting feeling!

Volume can be measured instantaneously using resonant sound.

My area of specialty is food engineering, and within the field, I'm engaged in research on "physical properties." By properties, we mean physicochemical characteristics, which become much involved with things like crunchiness, mouth-melting, and other aspects of mouth feel. I developed a volume-measuring technology which uses Helmholtz resonance, and I'm researching ways to control mouth feel by monitoring changes in physical properties.

My area of specialty is food engineering, and within the field, I'm engaged in research on "physical properties." By properties, we mean physicochemical characteristics, which become much involved with things like crunchiness, mouth-melting, and other aspects of mouth feel. I developed a volume-measuring technology which uses Helmholtz resonance, and I'm researching ways to control mouth feel by monitoring changes in physical properties.

Helmholtz resonance is the phenomenon where you hear a hooting noise when you blow across the mouth of a bottle. Since the register of the noise changes according to the volume of the container's contents, you can measure volume by investigating changes in the resonant sound. Typically, when you determine volume, you use a method involving the Archimedes principle of measuring the amount of water that overflows when a material is immersed in water, but this method requires that the object be immersed in a liquid, which is unsuitable for foods. There are also laser-based measurement methods, but these require considerable time for scanning. The new technology for measuring volume according to changes in sound is a new technique that compensates the existing drawbacks.

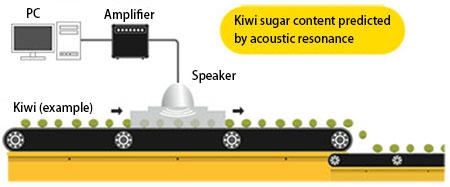

This measuring technology can be applied to many things, and what we've developed is an apparatus for predicting the sugar level of kiwi fruit. Kiwi fruits are ripened after harvest to convert their starch into sugar and bring out sweetness. So until now, it hasn't been possible to know their final sugar level at harvest. But if density can be measured, the amount of starch is known, and sweetness after ripening can be predicted. So we produced a density measuring apparatus which uses a Helmholtz resonator to allow measurement of kiwi fruit density.

each individual fruit after ripening. Fruits traveling on the conveyor belt pass into an open

Helmholtz resonator, and their resonant frequency is measured. Density is derived by

calculating volume and mass, allowing prediction of sugar level.

This measurement technique using Helmholtz resonance can be used without regard to liquids or solids. However, we did have a problem when measuring bread dough. Though the dough had clearly risen, and we expected the resonant frequency to increase, we didn't know why it decreased. The reason was air bubbles. Air bubbles in the bread had absorbed some of the sound and lowered the resonant frequency. So I thought that I would instead attempt to make use of this change in frequency. Bread has a quality indicator known as "texture", and with beer too, foaming determines flavor. Based on changes in resonant frequency, we assigned a numerical value to elements such as bubble size and volume, and texture. This allowed us to modify operating parameters in real time based on measurement results and get the flavor we expected.

I hope to understand the relationship between the physical properties and flavor of foods.

of a mixer is measured by attaching

acoustic tubes and a speaker.

Changes in the volume of whipped

cream and other foods are measured

during mixing and allow the fineness

of texture and other properties to

be determined numerically.

A consistent amount of foaming can

be achieved by stopping mixing at

the appropriate time.

Currently we're working together with beverage and confectionery manufacturers to pursue research on methods for evaluating things like bubbling and crunchiness. Working in partnership with industry outside academia, we've developed and marketed software for volumetric measurement based on Helmholtz resonance. In addition to personal computers, it's also compatible with smart phones and tablet terminals and can be used easily by anyone. In the future, I'm hoping that it won't be limited to just factories, development sites, or research facilities, and that it will find widespread use in ordinary households, much like a "scale" for measuring weight.

quality. The use of an acoustic

resonance technique allows

measurement of beer bubble

texture and foaming, as well as

head and other properties that

greatly determine consumer

palatability. The system is potentially

useful for product development by

industry, and joint research with

beverage manufacturers and others

is already underway.

The physical properties of foods are intimately linked to human sensation, but many aspects are subject to individual subjectivity, so these relationships remain unexplained. I hope to explain these aspects scientifically. Recently, we've also begun an initiative we call "humans as sensors." For example, we're considering testing in which we measure the vibration that a person perceives as crunchiness and determine whether we can produce the same sensation by artificially creating only the distinctive vibration that's part of the sensation.

What we hope to do by trying out different experiments is to gain, even slightly, a better understanding of the relatedness between the physical properties of foods and human sensation.